What is an automated guided vehicle system?

An automated guided vehicle or automatic guided vehicle (AGV), also called autonomous mobile robot (AMR), is a portable robot that follows along marked long lines or wires on the floor or uses radio waves, vision cameras, magnets, or lasers for navigation. They are most often used in industrial applications to transport heavy materials around a large industrial building, such as a factory or warehouse.

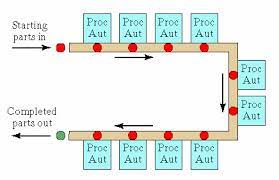

What are automated flow lines?

An automated flow line consists of several machines or workstations which are linked together by work handling devices that transfer parts between the stations. The transfer of work parts occurs automatically and the workstations carry out their specialized functions automatically. The flow line can be symbolized as shown in the following figure.

How is FMS different from batch production?

An FMS is a method used to manufacture and produce goods that is able to adapt to changes. Whether these changes involve the addition of new product types, the modification of existing product types, etc., an FMS can handle these and more. It provides manufacturing companies with a sharp competitive edge over their counterparts who do not use such flexible systems. Even so, however, there are both pros and cons associated with FMS.

How are adaptive controls work NC systems?

Adaptive control in CNC machines is the continuous monitoring of cutting load and automatic adjustment of cutting feed rate based on the load. During machining, the cutting load may suddenly increase because of local hard spots in castings or variation in the height of raw material. The load also increases as the tool wears out. This is how adaptive control works: You set a normal load level for an operation. If the load increases, the feed rate reduces to bring the load back to the normal level. If the load reduces (e.g., because the raw material is less than what the program was written for, or there’s a gap in the casting), the feed rate increases.

What is “balance delay” in line balancing?

The balance delay time is the amount of idle time on production assembly lines caused by the uneven division of work among operators or stations. It is related to the extent and way the total task is subdivided.

What is a flexible manufacturing cell?

A flexible manufacturing system (FMS) is a production method that is designed to easily adapt to changes in the type and quantity of the product being manufactured. The flexible manufacturing cell consists of one or several CNC machine tools or machining centres. The unit can automatically change tools and fixtures as needed to machine different workpieces.

What is a robot program?

Robot software (program) is the set of coded commands or instructions that tell a mechanical device and electronic system, known together as a robot, what tasks to perform. Robot software is used to perform autonomous tasks. Many software systems and frameworks have been proposed to make programming robots easier. Some robot software aims at developing intelligent mechanical devices.

Software for industrial robots consists of data objects and lists of instructions, known as program flow (list of instructions).

For example,

Go to Jig1

It is an instruction to the robot to go to positional data named Jig1. Of course, programs can also contain implicit data for example

Tell axis 1 move 30 degrees.

What are EIA and ISO coding standards?

EIA standards

The Electronic Industries Alliance (EIA) standards direct component marking, data modelling, colour coding and packaging materials. Products and services covered under this collection range from the smallest electronic component to the most complex systems used by the defence, space and consumer product industry. The American National Standards Institute (ANSI) accredits EIA standards, which help:

• Increase market share

• Boost quality levels

• Elevate customer satisfaction

ISO standards

The International Organization for Standardization (ISO) standards enable manufacturers to continually measure, evaluate, and improve the systems that ensure product quality and reliability. Consequently, manufacturers have to verify that their products always fit together properly, function accurately, and meet customer expectations.

The International Organization for Standardization is an organization that publishes standards for goods, services, and processes. The international standards act as benchmarks for quality and efficiency in a number of industries, the majority related to the supply chain and, as such, manufacturing.

The ISO 9000 family of standards help companies satisfy the needs of their customers, meet regulatory requirements, and achieve continual improvement.

What are CNC auxiliary functions?

Most CNC systems also contain some auxiliary devices as well as those devices called peripherals. Some of the important auxiliary devices may include

- Field Buses,

- Servo amplifiers, and

- Power supply devices, and so on.

Peripherals may include

- Keyboards,

- Graphic display interfaces such as monitors

- Printers, and

- Disk drives and tape readers.

The microprocessor selected is bus-oriented, and the peripherals can be connected to the bus via interface modules.

---

- The study material for AMIE/B Tech/Junior Engineer exams is available at https://amiestudycircle.com

- If you like the post please share your thoughts in the comment section

Comments