Answer the following questions in brief (2 x 10)

How is an arc obtained in arc welding?

Arc welding is welding using the heat of an arc as a heat source. In arc welding, a positive voltage is applied to the electrode (welding rod/wire) and a negative voltage is applied to the base material. This makes an arc occur from the base material to the electrode.

Why is neutral flame extensively used in oxy-acetylene welding?

Because it adds nothing to the metal.

What Is the significance of roll diameter with reference to the roll-separating force in rolling?

Low roll diameter results in the low roll contact area and consequently in the low absolute value of the roll separating force and the torque required for achieving a certain thickness reduction.

How do you compare forged components with cast components?

Forged steel is generally stronger and more reliable than castings and plate steel due to the fact that the grain flows of the steel are altered, conforming to the shape of the part. The advantages of forging include: Generally tougher than alternatives. Will handle impact better than castings.

What do you expect if, during the wire drawing process, the reduction attempted is more than the recommended value?

It may be due to higher friction between rolls and metals than required and also high roll separating force or drawing force is applied.

Why the whole of the material (billet) put in the container for extrusion is not extruded?

The extrusion is a single pass process. All billets are usually converted with an oxide layer. During a normal extrusion process, this oxide layer may be drawn into the cone of the product (reducing its strength characteristics) unless a laminar flow during the plastic deformation is ensured. So not all the billet can be used. The remainder (butt) contains oxide from the billet skinning. The butt is sheared off and discarded while another billet is loaded and welded and the extrusion process continuous.

How does extrusion compare with rolling?

Rolling can be used to offer the desired shape to the metal-like section, T-section, L-section, or channel section. Its also practised in order to provide final shapes to applications like rods, sheets, strips and pipes. Extrusion is a manufacturing process used to create objects of a fixed cross-sectional profile.

List down the properties of green moulding sand.

The basic properties required in moulding sand and core sand are

- adhesiveness

- cohesiveness

- collapsibility

- flowability

- dry strength

- green strength

- permeability

- refractoriness

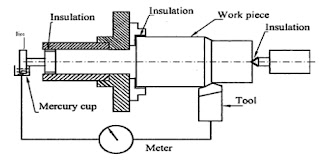

What is the most generally used method for measuring average chip tool interface temperature?

The most widely used method for measuring the average chip-tool interface temperature is the tool-work thermocouple as shown in the figure below:

What is AJM?

Abrasive jet machining (AJM) is one of the advanced machining processes where a high-velocity jet of abrasives is utilized to remove material from the work surface by impact erosion.

---

The study material for AMIE/Junior Engineer exams is available at https://amiestudycircle.com

Comments